cold production / academic / masdfab / 2022

FDM printing, fabrication logic, assembly

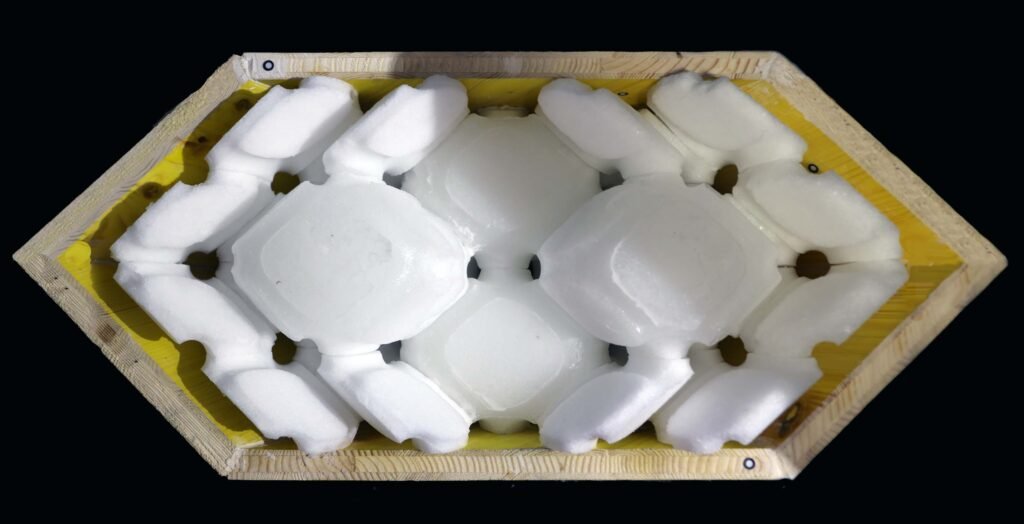

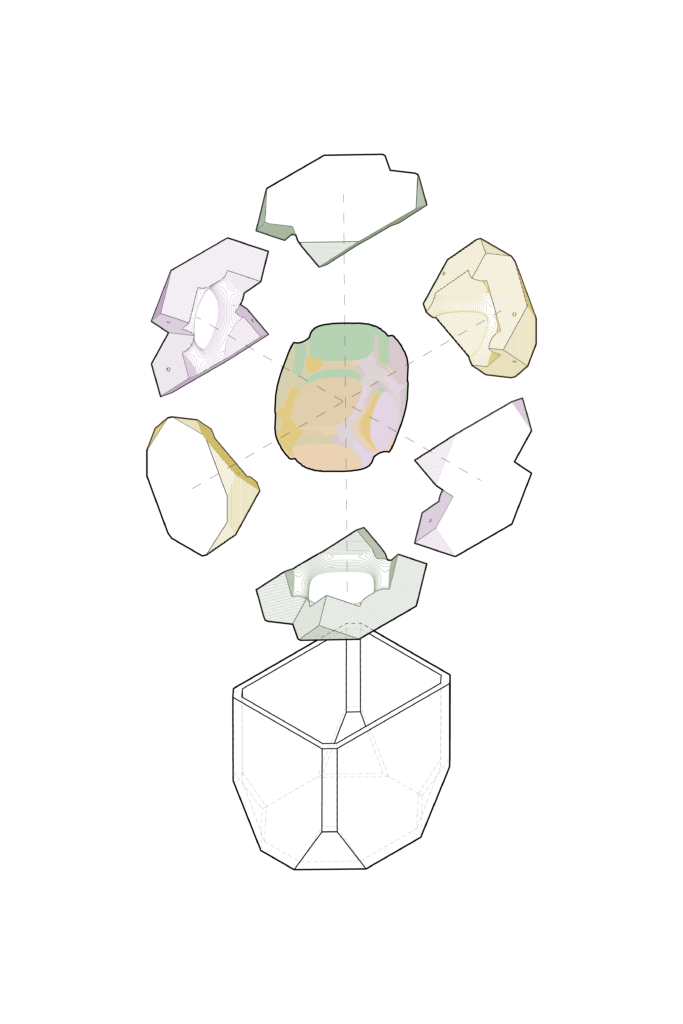

cold production explores a zero-waste fabrication method for concrete that uses digitally sculpted ice as a moulding material. The project explored spatial concrete lattices and their stacking principles. Using ice allows the creation of these hollow spatial lattices which can integrate functional gradation and reduce excess material. A series of modular 3d printed molds were used to create 12 different polyhedral stackable units which could align in different configurations. A formwork system made entirely with ice was used to then create 15 unique concrete objects which could then dry stacked in various configurations.

with Vasily Sitnikov, Remy Clemente, Yael Ifrah, Ko Tsuruta, Lena Kitani and MAS DFAB 2122 Students

All photographs : Vasily Sitnikov and MAS DFAB 2122

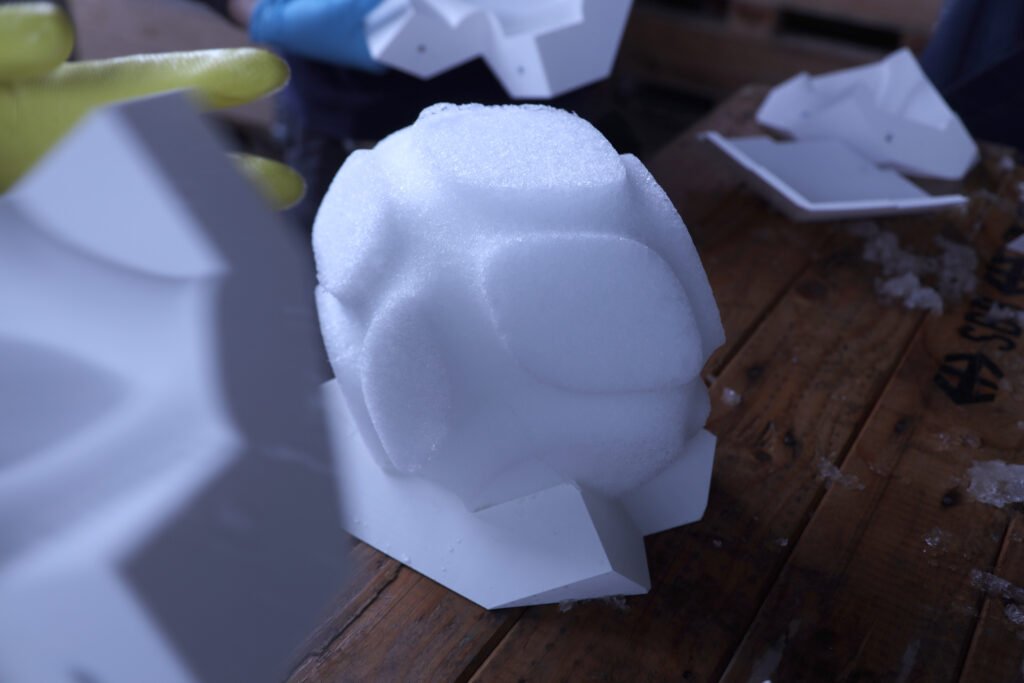

Using repeatable and stackable polyhedral geometries, a large variation in the weight of the realized forms could be created. The fragility of the snow molds and the process itself would add unique artifacts to the cast form, making this fragility and temporality rather permanent, once cast into the concrete mass. The snow, abraded from an ice skating rink and then melt around the concrete mass, is lost, yet embedded into the permanence of the form it creates.

A system of 3D printed PLA molds was used to hand press the collected snow into shape. The geometry of the polyhedron geometries was analyzed to avoid undercuts and generate molds with minimum number of separable pieces. Also, key factors like snow feeding direction, pressing surface location and ease of demolding were taken into account. Using a combination of three mold families, 12 different polyhedral geometries could be created, which when placed into a larger volume could create formwork for graded concrete blocks. To avoid waste and enhance the texture on the outside of the blocks, a larger snow mold was created to cast the concrete into. With this, a single wooden formwork could be used as a stamp to create copies of the generic outer snow mold.

All rights reserved, ananya kango 2023